What is Low-E Glass, 3 Main Benefits, How Is Low-E Glass Made

Material Summary

Low-E glass, short for low-emissivity glass, is the abbreviation of Low Emissivity in English. It is a film product with multiple layers of metal or other compounds coated on the surface of glass.

Simply put, this kind of glass can both transmit light normally and block some heat energy. When heat energy (infrared) from the sun or HVAC hits low-emissivity glass, it will be reflected back to the original space instead of being transmitted through the glass.

Material Properties: 3 Main Benefits of Low E Glass?

a. Energy saving and environmental protection

Using Low-E glass to manufacture building doors and windows can greatly reduce the transfer of indoor heat energy to the outdoors due to radiation, achieving ideal energy-saving effects. At the same time, it can significantly reduce the fuel consumed for heating, thereby reducing the emission of harmful gases.

b. Heat insulation

In winter, low-e glass can transfer less indoor heat to the outside, thus achieving a heat preservation effect. Similarly, in summer, it can transfer as little outdoor heat as possible to the indoor, achieving a heat insulation effect.

c. Excellent Optical Performance

The visible light transmittance of Low-E glass ranges from 0% to 95% in theory. The visible light transmittance represents the lighting quality of the room. The light transmittance of Low-E glass is much higher than that of ordinary white glass. It is more transparent visually and has higher lighting quality.

Material Classification

It can be classified according to the number of functional layers and light transmittance.

(1)Classification by functional layers

a. Single silver Low-E coated glass

Usually contains only one functional layer (silver layer), plus other metal and compound layers, the total number of film layers reaches 5.

b. Double silver Low-E coated glass

Usually has two functional layers (silver layer), plus other metal and compound layers, the total number of film layers reaches 9.

c. Triple silver Low-E coated glass

Usually has three functional layers (silver layer), plus other metal and compound layers, the total number of film layers reaches more than 13 layers.

(2)Classification by light transmittance

a.High Transparency

The light transmittance is over 70%, allowing a large amount of visible light to enter the room.

b.Medium Transparent

The light transmittance is 50%-70%, and it has a strong blocking effect on visible light.

c.Low transmittance

The light transmittance is below 50%, and it has a strong blocking effect on visible light.

Manufacturing Process: How Is Low-E Glass Made?

There are two mature process technologies for manufacturing Low-E glass:

a.Vacuum magnetron sputtering process (offline Low-E)

A technology that uses the magnetic field of the cathode surface to form an electron trap, allowing the electrons to drift close to the cathode surface under the action of E×B.

Features:

The firmness between the film layer and the glass surface is low, the film layer itself is relatively "soft" and easily scratched and abraded. The silver film is also prone to oxidation and denaturation when exposed to the air for a long time.

Precautions:

Offline Low-E glass cannot be used naked, that is, it cannot be used alone.

b.Chemical Vapor Deposition Process (Online Low-E)

A chemical technology that mainly uses one or more gaseous compounds or simple substances containing film elements to generate thin films through chemical reactions on the surface of a substrate.

Features:

The film layer has a high degree of firmness to the glass surface. The film layer itself is very "hard" and not easily scratched or abraded. The film layer will not oxidize or denature even when exposed to the air for a long time.

Precautions:

Online Low-E glass can be used naked, that is, it can be used alone.

Related Products

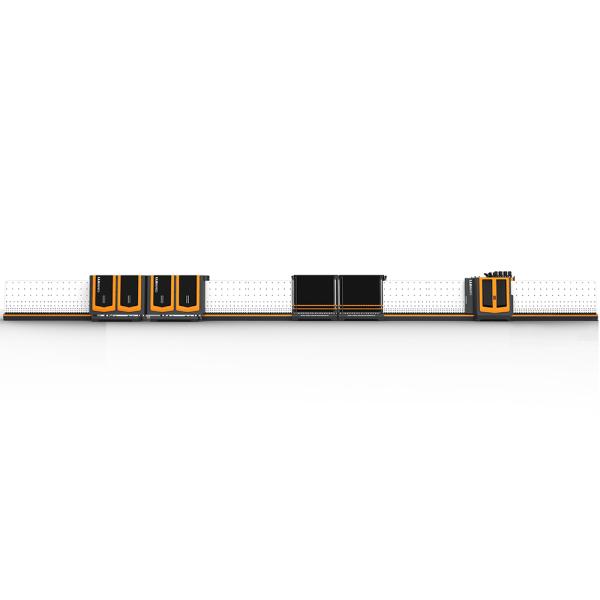

Automatic Jumbo Size Double Gas Filling Insulating Glass Production Line

Vertical Insulating Glass Processing Line to make glass processing more simple,intelligent and efficient....

Vertical Insulating Air-floating Glass Processing Line

Vertical Insulating Air-floating Glass Processing Line can press and fill gas Two pieces of IGU in once time, high work efficiency....

en

en Spanish

Spanish Russian

Russian Arabic

Arabic Portuguese

Portuguese Italian

Italian French

French Turkish

Turkish Vietnamese

Vietnamese Thai

Thai