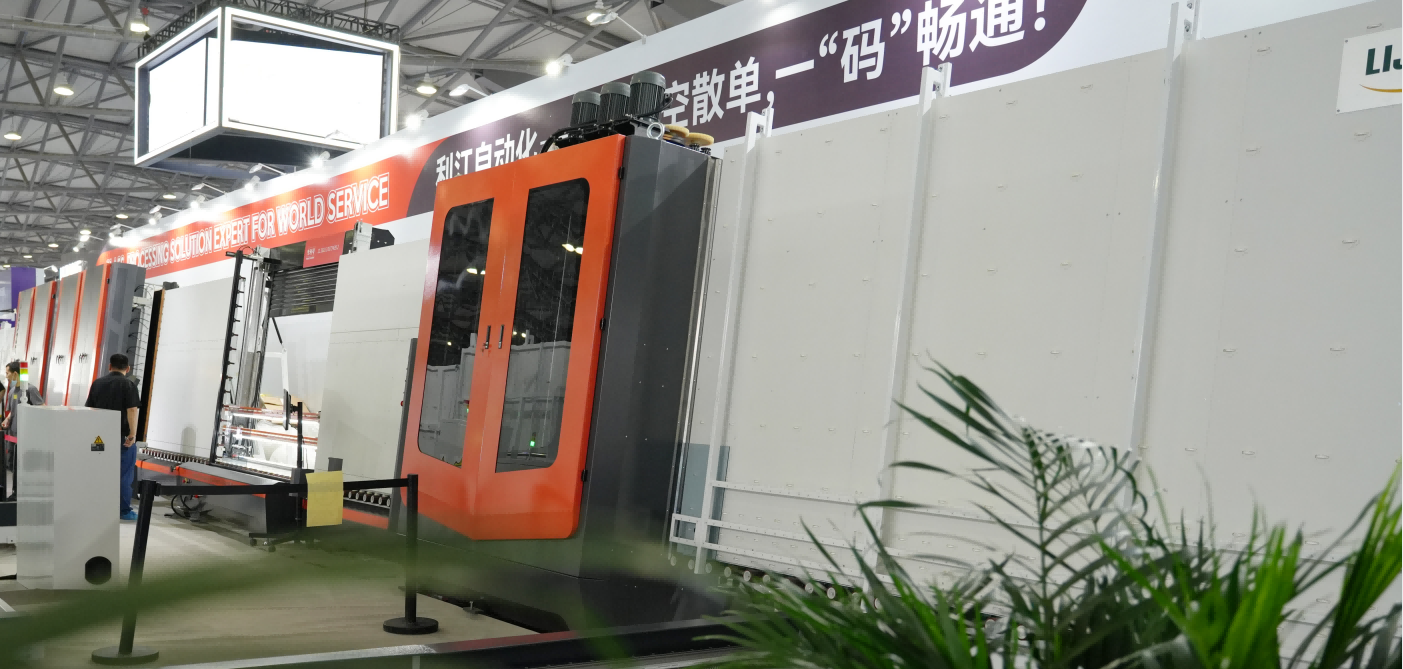

Vertical Insulating Air-floating Glass Processing Line

LJBZ2030GF/LJBZ2535GF

Maximum glass size:2500*3500mm

Maximum thickness of insulating glass:60mm

Washing brushes :6Pieces

Vertical Insulating Air-floating Glass Processing Line can press and fill gas Two pieces of IGU in once time, high work efficiency.

•Air floating back plate , to avoid the wheel scraching the glass and leaving wheel marks

•Two pieces of IGU could be pressed and filled gas in once time, high work efficiency

•Gas filling in pressing,automatic filling the glass in different areas according to the size of glass

•Germany Siemens PLC control system, touch screen interface

•Automatic identification of coated and Low-E glass

•3 pairs of soft brushes can wash online and offline Low-E glass

•The washing machine adopts SS material and waterproof device

•Water tank with automatic temperature control and water washing system

•Air heating system

•Air Fan automatic start and stop setting

•Noise reduction system

•Online display of washing speed

•Intelligent intermittent work, saving energy

•Adjustable pressing board to keep the plate pressing surface straight

•Automatic external rotary positioning system of glass

•Connection mode of aviation plug

•ERP system is optional

Vertical Insulating Air-floating Glass Processing Line has 7 sections:

01 transfer section

Coating detection mechanism, automatic detection of offline Low-e film

02 washing and drying section

03 discharge section

04 inspection and spacer frame installation section

05 transfer section with thickness measure

06 pressing sectionAutomatic Gas filling can set gas value and display the process of filling online with high gas concentration(Options)

07 discharge section

• Storage glass

• Can be connected to any brands of sealing robot machine

| Voltage | 380V50Hz3P | |||

| Total power | KW | 41 | 44.5 | 58 |

| Washing speed | m/min | 2~10 | ||

| Maximum working speed | m/min | 45 | ||

| Minimum glass size | mm | 450*280 | ||

| Maximum glass size | mm | 2000*3000(once) | 2500*3500 | |

| 2000*3500 (Twice) | 2500*4000 (Twice) | |||

| 2500*5000(Twice Add auxiliary suction cup) | ||||

| Flat glass thickness | mm | 3-15(Option 3-30) | ||

| Washing brushes | Pieces | 6 | ||

| Maximum thickness of | mm | 60 | ||

| insulating glass | ||||

| Total gas consumption | L/min | 1200 | ||

| Conveyer roll height | mm | 520 | ||

| Dimension (L*W*H ) | mm | 20200*3500*3200 | 23800*3500*3700 | 27200*3500*3700 |

EASTGLAZ - Glass Machinery

Vertical Insulating Air-floating Glass Processing Line

Send Inquiry - Vertical Insulating Air-floating Glass Processing Line

*Your email address will not be published. Required fields are marked.

Related Products: Insulating Glass Machine

Vertical Low-E Glass Edge Deleting Machine

Vertical Low-E Glass Edge Deleting Machine can automatically distinguish Low-E coating and deleting Low-E Glass Edge....

Automatic Insulating Glass Sealing Robot

Automatic Insulating Glass Sealing Robot can coat double glass, shaped glass, step glass, triple glass...

en

en Spanish

Spanish Russian

Russian Arabic

Arabic Portuguese

Portuguese Italian

Italian French

French Turkish

Turkish Vietnamese

Vietnamese Thai

Thai